24Hourly Consultation Hotline:

18262913779

Automation intelligent technology is widely used in industry, agriculture, military, scientific research, transportation, business, medical, service and family, etc. The use of automation technology can not only remove people from heavy physical labor

Jiangsu Jient Intelligent Technology Co., Ltd. is located in the west of Suqian Economic Development Zone, is a high-tech enterprise engaged in industrial automation industry and design and production factory supporting. The company specializes in complete sets of engineering automation, logistics conveying equipment system, as well as factory related equipment, lift series, fixture, tool cabinet, workbench, testing table, etc. Set design, manufacturing, installation, commissioning, after-sales service as one.

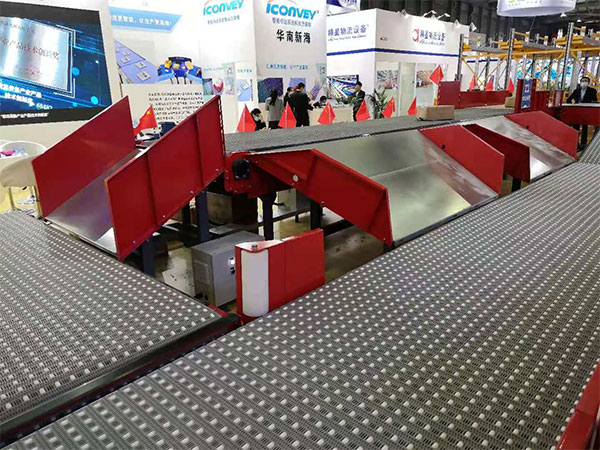

Assembly line is an effective combination of man and machine, the most fully reflects the flexibility of the equipment, it will transport system, accompanying fixture and online special machine, testing equipment organic combination to meet the assembly requirements of a variety of products.

Assembly line, widely used in meat processing industry, frozen food industry, aquatic processing industry, beverage and food, dairy processing industry, pharmaceutical, packaging, electronics, electrical appliances, auto parts, processing manufacturing, agricultural and sideline products processing industry and other industries.

The control cabinet is mainly used for high-rise buildings without tower water supply, fire deep well pump constant pressure water supply and other occasions to adjust the pump speed in a closed loop according to the real-time water use conditions, using well-known brands of inverter, intelligent controller, pressure sensor and pump to form a closed-loop control system.

Disconnect the power supply and check whether the rack of the control cabinet is grounded, and ensure that the grounding resistance is not greater than 4 ohms.

Three-dimensional structure, can make full use of warehouse space, improve the utilization rate of warehouse capacity, expand the storage capacity of warehouse;

In order to promote the integrated development of China's storage shelf industry and accelerate the construction of a solid barrier to the international development of China's storage shelf industry, China's storage shelf will take the connection of market supply and demand parties as an opportunity

Release time:2021/6/9 15:08:11 | Hits:951

With the continuous development of the Internet industry, the logistics and transportation industry has also been rapid development, a variety of logistics sorting equipment has also been expanded, of course, followed by some problems. For logistics sorting equipment, failure we also want to solve in time, Huaian transportation equipment manufacturers - Jieente according to their own experience and everyone say the fault and the corresponding solution.